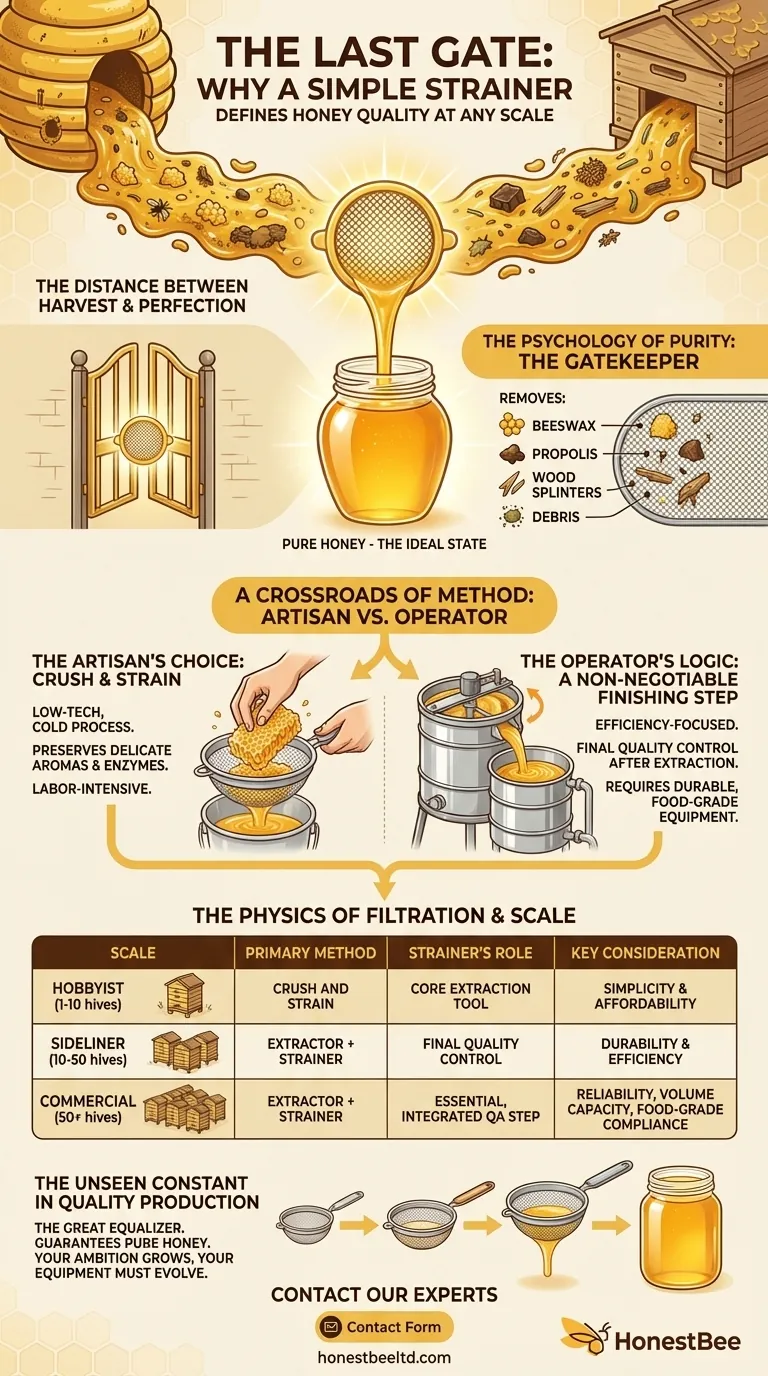

The Distance Between Harvest and Perfection

Imagine a single jar of golden honey. It’s luminous, pure, and perfect.

Between the raw, chaotic bounty of a hive—full of wax, propolis, and field debris—and that pristine final product stands a single, deceptively simple tool: the honey strainer.

This tool is more than a filter. It represents a fundamental decision point for every beekeeper. It’s a commitment to quality, a choice about methodology, and a reflection of the scale of their ambition.

The Psychology of Purity

Beekeeping is an act of stewardship. That sense of responsibility doesn't end when the frames are pulled from the hive. In fact, it intensifies. The goal is to present the honey in its most ideal state, and that begins with clarity.

A strainer is the physical mechanism for this ideal. Its fine mesh acts as a gatekeeper, intercepting particles that don't belong:

- Bits of beeswax

- Fragments of propolis

- Wood splinters from frames

- Other organic hive debris

Removing these isn't just about aesthetics. It's about delivering a pure, unadulterated product that honors the labor of the bees and the beekeeper. It's the first, most crucial step in quality control.

A Crossroads of Method: The Artisan vs. The Operator

How a beekeeper uses a strainer reveals their entire operational philosophy. The tool itself is simple, but its application sits at the center of two very different approaches to honey processing.

The Artisan's Choice: "Crush and Strain"

For the small-scale beekeeper, the strainer is the cornerstone of the "crush and strain" method. This is a beautifully low-tech process: honeycomb is cut from the frame, gently crushed, and the entire mixture is poured into a strainer set over a bucket.

Gravity does the work.

This method is labor-intensive. It requires patience. But its primary advantage is profound: it is a "cold" process that requires no machinery. It preserves the honey's most delicate aromas, enzymes, and beneficial pollen grains. The strainer enables the production of truly raw honey with minimal capital investment.

The Operator's Logic: A Non-Negotiable Finishing Step

As an operation grows, the time-cost of crush-and-strain becomes prohibitive. The centrifugal extractor becomes a necessity for efficiency. But the strainer does not become obsolete; its role simply shifts.

After honey is spun from the frames, it still contains fine wax particles and debris. Passing it through a strainer is the final, non-negotiable step before bottling. For a commercial apiary, this isn't just good practice—it's brand protection.

Here, the strainer is the last line of defense for quality, ensuring every jar meets a consistent standard. The demands on the tool are higher, requiring durable, food-grade materials that can withstand constant use and cleaning.

The Physics of Filtration and Scale

The decision to scale up an operation is a decision about process engineering. What works for 5 hives fails for 50. The equipment must evolve.

A hobbyist might use a simple nylon double-sieve strainer. A commercial operation, however, needs something more robust. They rely on multi-stage stainless steel straining systems that can handle large volumes without clogging or failing. The consistency of the mesh, the durability of the welds, and the quality of the steel become critical variables.

A failed strainer during a large batch process means contamination, lost time, and lost revenue. This is why professional apiaries and equipment distributors don't just buy a strainer; they invest in reliable filtration systems. HONESTBEE specializes in providing this commercial-grade equipment, engineered to perform consistently under the pressures of scaled production.

Filtration Strategy by Operational Scale

| Scale | Primary Method | Strainer's Role | Key Consideration |

|---|---|---|---|

| Hobbyist (1-10 hives) | Crush and Strain | Core extraction tool | Simplicity and affordability |

| Sideliner (10-50 hives) | Extractor + Strainer | Final quality control | Durability and efficiency |

| Commercial (50+ hives) | Extractor + Strainer | Essential, integrated QA step | Reliability, volume capacity, and food-grade compliance |

The Unseen Constant in Quality Production

From the backyard hobbyist to the commercial apiary supplying nationwide distributors, the honey strainer is the great equalizer. It is the one tool that is indispensable at every level of the craft.

It guarantees that the honey in the jar is just that: pure honey.

As your operation grows, your ambition is not just to produce more, but to produce better and more consistently. Your equipment must be a partner in that growth, offering reliability that matches your commitment. For robust strainers and other professional-grade supplies that form the backbone of a successful apiary, we can help.

ビジュアルガイド

関連製品

- 養蜂および蜂蜜ろ過用の円錐形ナイロン蜂蜜ストレーナーフィルターバッグ

- ステンレス鋼の二重層の蜂蜜のこし器ふるいフィルター

- 10Lステンレススチール電動ハニープレスマシン

- 蜂蜜濃縮および濾過除湿機 2T 容量の蜂蜜用

- ハニー櫛プレス機器を絞るための電動ハニープレスマシン